hardness test or tensile test|types of hardness testers : private label Vickers Hardness Test: In this test, a diamond pyramid indenter applies force to a small area of the material, which makes it suitable for measuring hardness at a microscopic level. The result . Pontuação ao vivo de vôlei no Sofascore - acompanhe os pla.

{plog:ftitle_list}

29 de jun. de 2022 · Music. Aug 8, 2022. Can you sort the Taylor Swift songs by album? Test your knowledge on this music quiz and compare your score to others. Quiz by Mersu.

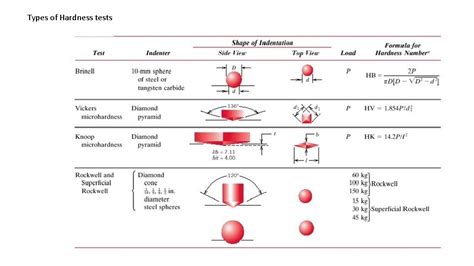

types of hardness tests

Hardness testing is used to evaluate the resistance of a material to surface deformation, while tensile testing is used to evaluate the overall strength and ductility of a material.Vickers Hardness Test: In this test, a diamond pyramid indenter applies force to a small area of the material, which makes it suitable for measuring hardness at a microscopic level. The result .Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond).

Hardness testing. Hardness testing is a mechanical test used to measure the resistance of a material to indentation or deformation. It is commonly used to determine the hardness of metals, but it can also be used on other .

types of hardness testing methods

types of hardness testers

Common methods of hardness testing include Rockwell, Brinell, Vickers, Knoop, and Shore hardness testing. Each method uses different techniques to measure the hardness of a .Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are . The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when .

How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials .

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; . often expressed as percent elongation or percent area reduction from a tensile test. In practice, these hardness tests could, for instance, assist in determining the viability of steel to be used in a high .Tensile Testing is a form of tension testing and is a destructive engineering and materials science test whereby controlled tension is applied to a sample until it fully fails. This is one of the most common mechanical testing techniques. It is . Setup. The tensile test is one of the most important testing methods for characterizing or obtaining material parameters. In the tensile test, for example, it is determined which load a material can withstand until it begins .

Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).; However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not .Shown below is a graph of a tensile test for a common steel threaded rod, providing a good example of a general metal tensile test. The units of engineering stress are ksi , which stands for a thousand pounds per square inch.

m272 water test kit package

Ultimate Tensile Stress (UTS) and Ductility. It may be noted at this point that it is common during tensile testing to identify a “strength”, in the form of an “ultimate tensile stress” (UTS).This is usually taken to be the peak on the nominal stress v. nominal strain plot, which corresponds to the onset of necking.

a Brinell hardness values up to 450 HB w Brinell hardness values up to 450 HB were determined using a steel ball indenter, those above this value were determined with a hardmetal ball.. NOTE 1 Values in parentheses are those lying outside the defined range of the standard test method but which may used as estimates. NOTE 2 The value of the tension test are not based on .A tensile test is more accurate because it provides an actual reading of the tensile strength. When a material is cold rolled, the top and bottom surfaces (“A”) become harder as they are exposed to more work than the round side edges (“B”).Tensile test: Tensile strength, yield strength/offset yield, strain at break, reduction of area: Machined test pieces: 9.8: Head soundness test: Head strength: Bolts and screws: 9.9: Hardness testing: Hardness to Vickers, Brinell or Rockwell: All bolts and screws, in particular those which are too small for a tensile test: 9.10: Decarburization .The Brinell hardness number can be correlated with the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore . Brinell hardness test – Part 3: calibration of reference blocks". "EN ISO 6506-4:2014: Metallic materials – Brinell hardness test – Part 4: Table of hardness values". US .

Rockwell B Test Brinell 10/500 Hardness Test Average 99.7 227.5 Conversion table value 95 220 Table . Hardness values for aluminum. 6061 Aluminum Rockwell B Test Brinell 10/500 Hardness Test Average 53.825 95.6 Conversion table value 54 87 Table . Hardness values for brass. The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control.

1. rockwell hardness test 10 2. vickers hardness test 13 3. impact test 16 4. tensile test 21 5. compression test 26 6. shear strength test 29 7. heat treatment 32 8. wear test 35 9. microstructure 39 10. brinell hardness test 43 11. torsion test 46 12. fatigue test 49 13. bending test 53 14. ultrasonic test 56 15. magnetic particle test 58ARDL regularly measures Original Physical Properties of materials submitted by customers. Original Physical Properties testing performed by ARDL includes tensile testing (tension), elongation and hardness measurements. Tensile and elongation testing measures the force required to break a specimen and the extent to which the specimen stretches or elongates to .Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength 2. Functionality • Test to confirm ability to function as designed.

Tensile strengths of 2.0 to 5.0 mol% YâOâ-stabilized ZrOâ polycrystals are described using the newly developed tensile testing method. The tensile test was conducted by attaching three strain .

Hardness values as well as yield and tensile strength values were compiled for over 150 nonaustenitic, hypoeutectoid steels having a wide range of compositions and a variety of microstructures.

One of the most common destructive tests used to determine mechanical properties is the tensile test. This test is used to provide information about the tensile strength, yield strength, and ductility of the primary metals and metal alloys. . General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness . Metal Tensile Test. The results from the Tensile test provided data which can be used to calculate other useful engineering data by a series of different calculations. All results from tensile test can be found in Table 1. The tensile strength of each of the metals was calculated by: Tensile Strength = F A i

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.Tensile testing is a basic mechanical measurement to detect how a material resists loaded tensile forces until it fractures. From: Digital Manufacturing, 2022. . Hardness Test. Hardness is defined as the resistance to plastic deformation by indentation. Brinell, Rockwell, and Vickers or Knoop are the most common indentation hardness test .For automated tensile tests, the testing machine is supplemented with a robotic testing system, which removes specimens from a magazine and inserts them in the specimen grips of the machine.A 2D code reader, cross-section measuring device or, depending on the test, a hardness tester or roughness measuring system can also be connected. Tensile or tension testing is a fundamental and most commonly used test for the characterization of the mechanical behavior of materials. The test consists of pulling a sample of material and measuring the load and the corresponding elongation. Main properties.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds. Exploring Elongation TestingElongation testing, a cornerstone of material science, reveals a material's ductility and strength when under tensile stress. By stretching a sample until it breaks, this test measures how much a material can deform before failing. In industries prioritizing safety and durability like automotive and construction, this insight is crucial. .

The tensile strength R m is determined with a tensile test (e.g. in accordance with the ISO 6892 series of standards (for metallic materials), or the ISO 527 series of standards (for plastics and composites)).. The tensile strength is calculated from the maximum achieved tensile force F m and the specimen cross-sectional area at the start of the test: .When testing coatings, scratch hardness refers to the force necessary to cut through the film to the substrate. The most common test is Mohs scale, . The latter, which is conventionally obtained via tensile testing, captures the full plasticity response of the .

hardness tester for thin material

WEBJaine Cassu - Mais na bio🔥 pictures and videos on EroMe. The album about Jaine Cassu - Mais na bio🔥 is to be seen for free on EroMe shared by coxamac. Come see and share your amateur porn.

hardness test or tensile test|types of hardness testers